JimaFor

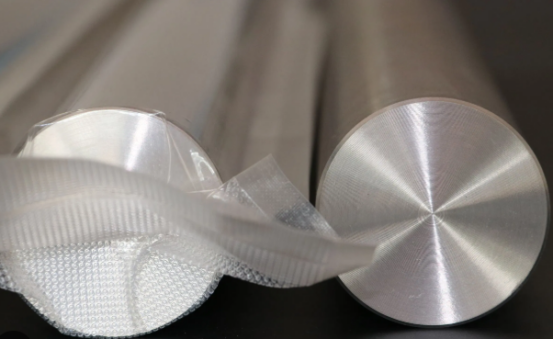

JimaFor provides professional R & D services and customized

production of high - end components

Our main business specializes in the R & D and custom production of

high - end metal components, catering to the needs of various

industries and focusing on complex and challenging products.

Our Advantages

Our strength lies not only in the ability to manufacture and supply

forgings, castings, and machined parts but also in our strong

optimization and integration capabilities. We are able to integrate

advanced manufacturing technologies from across China, providing

customized solutions tailored to meet the unique needs of our

customers.

Our Mission

By integrating advanced technologies and manufacturing resources,

we are dedicated to addressing the following challenges for our

customers: technical issues, sourcing, quality, lead time, and cost

concerns.

6, Mechanical/Mechanical Properties of Titanium and Titanium Alloy

Plates

6, Mechanical/Mechanical Properties of Titanium and Titanium Alloy

Plates